Some highlights of work

Featured Products

-- Pablo Picasso

At M.S Dyeing Printing & Finishing Ltd., we employ the latest circular knitting machines with a remarkable capacity of 110,000 kilograms per day. Our knitting process is a hallmark of innovation and efficiency, intricately interlacing yarn to produce high-quality knit fabrics. With a focus on sustainability and excellence, we ensure the production of comfortable, durable, and environmentally responsible knit textiles that meet the highest industry standards.

M.S Dyeing Printing & Finishing Ltd. excels in the dyeing process, employing cutting-edge dyeing and CPB (Continuous Processing Batch) machines. With an impressive capacity of 110,000 kilograms per day, our state-of-the-art equipment ensures precise color application, excellent color fastness, and operational efficiency. We are dedicated to delivering vibrant, high-quality dyed fabrics while adhering to sustainable practices, making us a trusted choice in the textile industry.

At M.S Dyeing Printing & Finishing Ltd., our cutting process is a testament to efficiency and precision. We employ cutting-edge technology, including automatic cutting machines from Italy, spreaders, and manual cutters, enabling us to prepare materials for stitching with a capacity of up to 120,000 pieces of garments. This combination of automation and skilled craftsmanship ensures the accurate and efficient preparation of fabrics, setting the stage for high-quality garment production.

M.S. Dyeing and Printing Ltd., a leading full composite knit garments manufacturing unit, employs cutting-edge equipment in its printing and embroidery processes. Utilizing state-of-the-art technology, the company ensures precision and intricacy in designs, enhancing the visual appeal of their knit garments. The advanced printing and embroidery machinery not only elevates the quality of the finished products but also positions M.S. Dyeing and Printing Ltd. as an industry leader, delivering innovative and embellished knitwear to meet market demands.

M.S Dyeing Printing & Finishing Ltd. excels in the all-over printing (AOP) process, driven by state-of-the-art flatbed and rotary printer machines with a remarkable capacity of 20,000 kilograms per day. Our advanced AOP capabilities allow us to create intricate and vibrant patterns, ensuring the highest quality and precision in every print. We take pride in our capacity to deliver innovative and visually striking designs across a wide range of textiles.

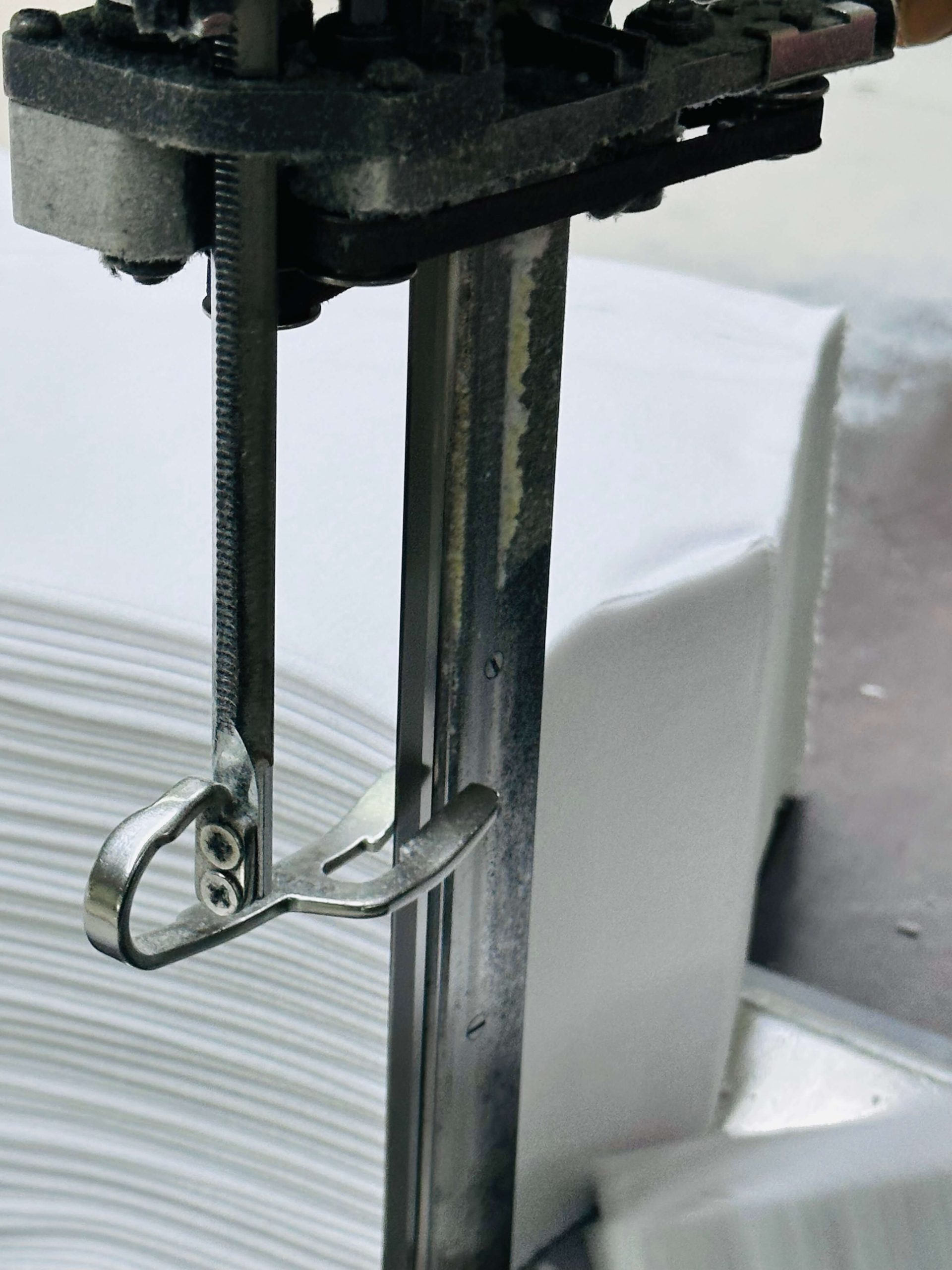

M.S Dyeing Printing & Finishing Ltd. boasts a cutting-edge sewing process facilitated by the latest technology, including the smoke-type sewing machine. Our highly skilled workforce ensures precision in every stitch. With an unwavering commitment to quality and efficiency, our sewing process guarantees the creation of well-crafted, durable garments that meet the highest industry standards. We take pride in delivering products that blend innovation and craftsmanship to fulfill diverse fashion needs.

M.S Dyeing Printing & Finishing Ltd.'s state-of-the-art finishing process spans 230,000 square feet and utilizes cutting-edge equipment. Our finishing process includes HYDRO-EXTRACTORS for efficient moisture removal from dyed fabrics and computerized tensionless dryers that facilitate instant fabric dyeing, soft setting, and calendaring. These advanced technologies guarantee the highest quality in the textile finishing, ensuring our products meet rigorous industry standards while staying ahead of evolving fashion trends.

At M.S Dyeing Printing & Finishing Ltd., our packaging process is a hallmark of efficiency and flexibility. We take pride in delivering on-time solutions for packaging any size and quantity as per our clients' unique requirements. With meticulous attention to detail and a commitment to meeting delivery deadlines, our packaging ensures that every order is prepared, protected, and ready for seamless distribution, aligning with our dedication to customer satisfaction

We embarked on our manufacturing journey in the knit garment sector nearly four decades ago. In 2005, MSDP&F emerged as our latest venture, aiming to meet the ever-expanding global demand for knit garments. The year 2020 marked a significant milestone when we introduced the world’s best CPB (Cold Pad Batch) Dyeing, large-scale Dyeing finishing, and ALL Over Print (AOP) Printing, consolidating these processes within the same facility. With an ongoing commitment to infrastructure development, including nine new buildings and ten additional sheds, our ultimate goal is to provide a comprehensive “One-Stop Solution” for the global RMG industry. Our unwavering vision is to prioritize customer satisfaction.

M. S. Dyeing, Printing & Finishing Ltd has a dedicated and skilled workforce of more than 6,500 employees and had an annual turnover of USD 96 Million for the year 2019-20. M. S. Dyeing, Printing & Finishing Ltd supplies quality apparels to globally renowned retailers and is focused on upholding the reputation of the readymade garments industry of Bangladesh.

We Believe, an industry is not only a source of income, rather it should reflect on sustainable socio-economic development of the country. We know that success is not an individual; the collective effort of everyone accomplishment for an enterprise as well as for the whole nation.

Navigating the RMG World’s New Frontier: Our dedication lies in crafting top-tier products with impeccable precision and ensuring on-time delivery for our valued clients. Our core business philosophy is centered on achieving absolute client contentment.

"MS Dyeing: Crafting function-focused designs, a hallmark of unparalleled uniqueness."

"MS Dyeing: Exemplary quality policy ensuring excellence in every thread."

"MS Dyeing: Swift precision, a unique blend for exceptional efficiency."

"MS Dyeing: Innovative solutions, transforming challenges into opportunities with precision."

M.S. Dyeing, Printing & Finishing Ltd. operates a top-tier RMG manufacturing facility with a remarkable daily production capacity of 250,000 garments. The manufacturing area spans 6,86,936 square feet and is further complemented by an additional 92,172 square feet of open space. In total, our facility covers an impressive 7,79,108 square feet, where quality and efficiency are paramount.